Systems Reef Advantages

Up to 30% cost reduction

We’ve benchmarked against 2025 Australian standard commercial supply and install rates for:

Grid ceilings, concealed steel ducting, including flexible ducting and diffusers.

Exposed ceilings, exposed steel ducting, including semi rigid ducting and diffusers.

When compared like for like on a typical commercial floorplate, Systems Reef offers up to a 30% cost reduction to grid ceilings with concealed steel ductwork, and offers a comparative price to exposed ceilings with exposed steel ductwork*.

*Each building and locality is different, end savings may increase or decrease due to your precise requirements, building, market and location.

15% less operating energy

Systems Reef has been designed for air. We’ve used computational fluid dynamics to limit pressure losses, and the leakage that occurs in standard ductwork. The branching layout eliminates all 90degree bends. The 3D printing process allows the system to be constantly tapering, enabling pressure to be maintained.

Our patented asymmetric cross section is tuned to further limit pressure losses, and when combined with our integrated pores which allow lower air velocities, energy savings are anticipated to be in the realm of 15%*

*Realisable energy savings will increase or decrease according to climate, building type and HVAC system.

85% less embodied carbon

Systems Reef is made from a proprietary low embodied carbon material which uses recycled polycarbonate - a significant improvement on steel.

An embodied carbon assessment has been undertaken in collaboration with The Footprint Company examining scope 3 emissions for a benchmark project located in Sydney Australia using 2021 carbon rates. Reductions are benchmarked to a typical fitout with suspended ceiling and concealed steel ductwork.

Our continually tapering system uses less material than a conventionally manufactured duct. 3D printing also allows material wastage to be reduced to less than 2% - in comparison to sheet-based manufacturing which can have wastage rates as high as 20%.

Embodied carbon reductions may be higher or lower depending on location and project requirements.

Circular Economy

Systems Reef is designed for the Circular Economy. Our 3 primary components are customised for each project, all joints are click and connect, and designed for deconstruction. Making change simple at a fraction of the cost of traditional systems.

Components can easily be relocated if required, and unused components can be recycled, or crushed up and printed again.

70% reduction in installation time

Installing steel ductwork is difficult and comes with various health and safety issues.

Our components are on average 70% lighter than steel duct, and click and connect joints eliminate all screw fixings. 25% less fixing points and a simpler hanging system reduces heavy manual labour. Integrated diffusers eliminate the need for a ‘2nd fix’ by installers.

Systems Reef reduces installation time by up to 70%*. Each component is digitally inventoried and can be checked on site for location.

*70% is based on time reduction in comparison to installation of exposed steel ductwork and diffusers. The reduction includes savings from reduced fixings, lightweight hanging requirements and click and connect jointing system. Install times may vary project to project.

Advanced Comfort

Air conditioning is the number one tenant complaint in offices around the world. Improving user comfort is critical to our mission at Systems Reef.

Systems Reef delivers air through thousands of tiny pores, typically at lower velocity, along the length of each linear component. This reduces the likelihood of perceptible draft, improving comfort in comparison to standard diffusers.

Image: Systems reef during a laboratory smoke test - smoke is used to visualise the behaviour of air to verify performance.

AI powered design

Systems Reef is designed using custom automation processes powered by AI. All relevant performance data is able to be input into the scripts to meet requirements. Production files are a direct output of the design files ready for robotic printing. Our processes are 95% automated, slashing design and development time and increasing accuracy and optimisation.

Compatible

Systems Reef is designed to plug into new or existing Variable Air Volume (VAV) or Fan Coil systems in open plan environments, without ceilings.

The system delivers air from the units to the floorplate. The integrated pores eliminate the need for typical diffusers. Optimised design and elimination of redundancy typically results in a reduction of cross-sectional area in comparison to standard systems.

Customised

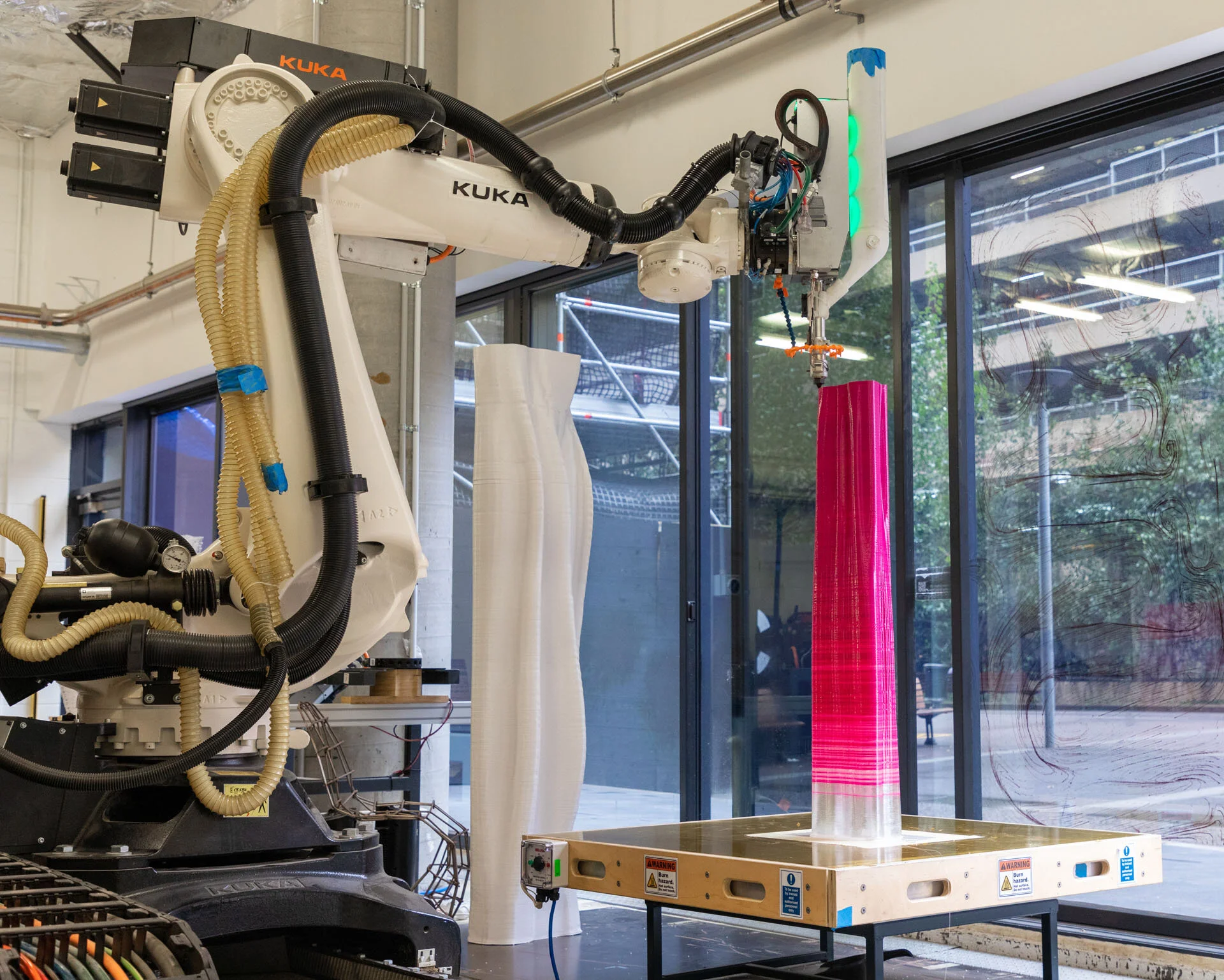

Systems Reef is 3D printed using robots. We have automated approximately 98% of our design to manufacturing processes.

The complete integration of design to production allows us to be able to customise our product to your project requirements. 3D printing also significantly reduces material waste and delivers high levels of quality. Each component is inventoried with its unique data including cost, embodied carbon, weight, fixing points etc.

We are able to offer Systems reef in a range of standard colours as well as provide a colour matching service on request.